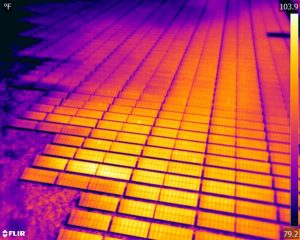

More frequent infrared inspections for example quarterly or semiannually should be performed where warranted by loss experience installation of new electrical equipment or changes in environmental operational or load conditions.

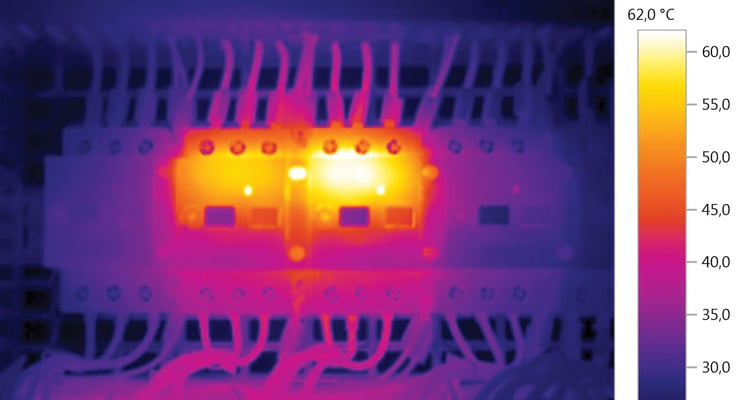

Ir scan electrical panels.

The benefit of removing panel and or dead front covers on electrical apparatus.

This would be wonderful from the standpoint of logistics manpower and labor hours.

Just as in the case of the electrical systems inspecting the hvac in a commercial building or factory setting is more engaging and therefor more expensive.

Routine infrared inspections of energized electrical systems should be performed annually prior to shut down.

The use of infrared scanning to detect early indications of system failure is a preemptive measure that can minimize equipment breakdown and downtime.

Infrared scanning of electrical components and systems should be part of any preventative maintenance program and performed on a routine basis.

The infrared electrical testing allows for inspection of a large amount of electrical equipment in a short time as opposed to the alternative method of physically inspecting and tightening electrical components.

Conducting infrared electrical panel inspections.

Since electrical panels must be removed thermographers often come in close proximity to energized components.

Inspecting the insulation of a home or building involves using the infrared imaging camera to scan every single square inch of the building.

Reduce the risk of arc flash and electrocution with fluke s infrared windows.

This paper discusses the national fire protection association nfpa 70e the occupational safety and health administration and how they apply to infrared inspections of electrical equipment.

Also conducted a brief ir scan with the camera on the exterior of the panel.

The digital and infrared images are illustrated below in figure 14.

The infrared electrical systems survey is typically conducted on an annual basis as part of a regular preventive maintenance program.

Infrared electrical thermography is a useful tool that can recognize stressed elements of your electrical installation before they break down or cause a fire.